by harrisonburgarchitect | Aug 19, 2015 | architecture, Harrisonburg Architect, project update

Read our progress on the Harmony Square Dairy Queen here:

Part 1 – Part 3 – Part 4 – Part 5

Dairy Queen prototype

It seems like just last week that we wrote about the ground breaking on our sweetest project. Now the new Harmony Square Dairy Queen on 42 North in Harrisonburg has a foundation, slab, and walls.

We have been busy processing questions from the general contractor, attending site meetings, and coordinating between various parties involved in the project.

This Dairy Queen is moving out of the shopping center where it has been serving ice cream treats for many years to provide easier drive thru access and breakfast. The new store will have more seating available both inside and outside. We are really looking forward the grand opening in December 2015.

by harrisonburgarchitect | Aug 14, 2015 | architecture, Building Science, Harrisonburg Architect

There are some common things on the wish list for most custom homes. Clients want an open floor plan, lots of light, a beautiful kitchen, luxurious master bathroom, and connection to the outside. However, it is not often asked for – healthy indoor air quality.

Materials, structure, and the heating, ventilation, and cooling systems all contribute to indoor air quality. Making the right selections in all these areas is critical.

Fireplace

There are common elements that impact indoor air quality. A fireplace is a leak in the building envelope. When there is a leak, it will either bring dirty air into the home or pull dirty air through the building envelope into the home. This also happens with restroom ventilation fans, crawl space, and duct work.

Ductwork

If the ductwork is not tight, it will actually spread dirty air around your house. Insulate it right and seal it tight.

Building Envelope

The building envelope is critical in the design of a home for healthy indoor air quality. Keeping the air from moving through the walls will allow you to filter make up air through a filtration system. This will, along with a fresh air system, keep the air flowing through your house healthy and clean.

Moisture

Also, and this one has big impacts to durability and indoor air quality, keep the water out of the wall system. Water infiltration in your home will contribute to indoor air quality faster than anything else.

Finally, the materials used in your home impacts indoor air quality. Do the materials you use have VOC’s? What chemicals will they off gas into your air? Are they easy to clean? What do you use to clean the materials used? All of these questions impact indoor air quality and should be considered.

It is not going to be on the top of your list, but include healthy indoor air quality when building or renovating.

by harrisonburgarchitect | Aug 10, 2015 | architecture, Building Science, Harrisonburg Architect

Green Term Defined: Net Metering

Net Metering is a method of crediting consumers for the electricity that is generated on their home or business in excess of the total electricity that they have used.

Consumers that have solar or wind power on their home or business offset their electricity that they use with the electricity they are producing. If you were to generate more electricity than needed in a billing period then the electric meter turns backwards indicating net excess generation. This is how the electric company tracks your total energy usage. It is also how you take advantage of needed power at night when solar pv is not producing – you essentially are using the power grid as your battery and paying if you use more than you create.

Net Metering laws vary from area to area and the amount that the power company pays you for excess will vary.

by harrisonburgarchitect | Aug 6, 2015 | architecture, Building Science, Harrisonburg Architect

Vote for us click HERE

We are honored to be included in another design awards program. We found great success in the Marvin Windows Challenge finishing in the top 5 in the country. Now we have a house in the Integrity Red Diamond Awards that is located in downtown Harrisonburg. Please consider voting for this home if you like what we did for our clients. Please vote for us in the Red Diamond Awards!

Built by Beck Builders and landscaping done by the Natural Garden, this home is a great example of how to conserve green space while providing a comfortable energy-efficient home.

This 2,500 square-foot, four-story home was built on an in-fill lot in the heart of Harrisonburg’s historic Old Town neighborhood. The home features four bedrooms, an open living room / kitchen, one car garage and a home office. There is a bridge connecting the front door to the parking area and a roof deck with expansive views stretching as far as James Madison University. The homeowners wanted an energy-efficient, contemporary-style cottage look that would blend into the historic neighborhood.

by harrisonburgarchitect | Aug 3, 2015 | architecture, Building Science, Harrisonburg Architect

Green Term Defined: Carbon Neutral Building

Carbon Neutral Building is the process of taking into account measuring, reducing, and offsetting carbon energy used by the building. A typical carbon neutral building integrates passive design, high performance building envelope, energy-efficient systems, and on-site renewable energy.

In order to measure carbon neutrality the building must have system boundaries – meaning an understanding of what is being measured. Are building material manufacturing processes included? What about travel to and from the building during construction or post-construction? What parameters are most important should be carefully considered and transparent to the client.

Carbon Neutrality for buildings can be supplemented by purchasing of green power. However, this misses the intent in my opinion.

by harrisonburgarchitect | Jul 31, 2015 | architecture, Harrisonburg Architect

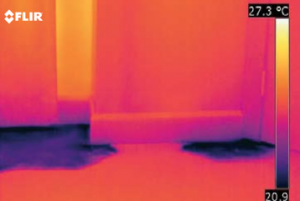

Your heating and cooling system should be inside your thermal envelope or you are wasting money. We often find the HVAC system in homes in unconditioned attic, basement, or crawl spaces. That means you are trying to cool or heat air and send it through a space that is working against that goal. You are also probably growing mold.

This not only means the HVAC mechanical equipment should be on the conditioned side of the insulation, it means the duct work should as well. While duct work has insulation, it is not as much insulation as you should have between inside and outside of your home. Keeping the mechanical system and duct work on the inside of the insulation will reduce the amount of energy required to achieve comfort.

If you mechanical system is in an unconditioned space, you are wasting money. The best solution is to add insulation to the space placing the mechanical system inside the thermal envelope. It is not a simple problem to fix if it was not done with building science in mind to start. However, it is a problem that should be solved for lower energy bills and higher comfort.