Green Term Defined: Cellulose Insulation

Cellulose Insulation is a low-thermal-conductivity material use to reduce heat loss and gain from a building. It is also a great noise transmission reduction materials as it is made of cellular materials.

There are four major types of cellulose insulation. They have the general characteristics of being dry, spray applied, stabilized, and low dust cellulose.

Dry Cellulose is used in renovation work where you are spraying in material through holes in a wall. This type of insulation will settle over time as gravity pulls it down. To avoid this settling problem a method called dense-pack is used which requires more than just small holes for installation.

Spray-applied Cellulose is a wet installation that mixes in adhesives during installation. This approach will reduce air movement through the insulation. It does force a drying period for the wall after installation to allow the mixture to dry out. Drywall should not be installed until the material has dried per manufacturers recommendations.

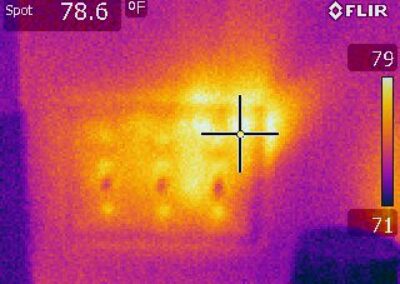

Stabilized cellulose is often found in flat installations such as attics. It uses water and adhesive in order to reduce settlement and to reduce air movement through the material.

Low-dust Cellulose is the type of insulation used in homes where the occupants may be sensitive to dusts.

Cellulose insulation has a lower thermal performance rating than does spray foams and it is not as air tight. It does provide a higher level of sound insulation than spray foam so could be used in homes where sound isolation is a priority. Cellulose typically contains between 75-85% recycled paper – often newspaper. It has the lowest embodied energy of any insulation type on the market. The most compelling advantage for this insulation type is that it has thermal storage properties – so it acts similar to a mass wall in storing heat during the day and allowing it out at night.